Welcome to

On Feet Nation

Members

-

uzair Online

-

-

Blog Posts

Hiring will be shaped by technology

Posted by Guddu BHaiya on February 21, 2025 at 2:04pm 0 Comments 0 Likes

It merges business utility and inclusion. Beyond addressing labor shortages, tapping into the hidden workforce also aligns with broader societal movements toward inclusivity and social responsibility.

https://varecha.pravda.sk/profil/adammakaw/o-mne/…

Continue

Hokibro: Situs Resmi No.1 dengan Jackpot Besar dan Keberuntungan Maksimal

Posted by John Snow on February 21, 2025 at 2:03pm 0 Comments 0 Likes

Ragam Permainan Menarik di Hokibro

Sebagai platform judi online terkemuka, Hokibro menyediakan berbagai jenis permainan yang dapat… Continue

Seline

Posted by Jerold Galarza on February 21, 2025 at 1:55pm 0 Comments 0 Likes

Top Content

Machining Aluminum: A Few Things You Need to Know

Aluminum is soft, ductile, malleable, and pliable, unlike many other metals that can be hard, brittle, and temperamental. That means aluminum should be easy to machine, right?

Well, it’s not quite that simple. Like machining any other material, aluminum possesses unique qualities that must be understood for success.

Here are a few things you need to…

ContinueAdded by Geoffrey Less on November 3, 2022 at 9:25am — No Comments

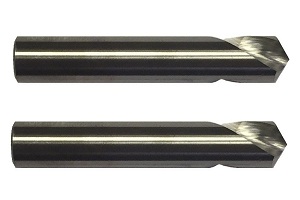

best Spot Drills vs. Center Drills

One of the common queries on the web (related to machining, at least) is “What is the difference between a spot drill and a center drill?”

Since these types of drills are used for similar applications (but not the same) some explanation is warranted.

Let’s take a look at these two different types of drills.

What Is a Spot…

ContinueAdded by Geoffrey Less on October 31, 2022 at 1:00am — No Comments

Indexable vs. Solid Carbide Thread Mills

When milling threads (as opposed to using a tap and die), machinists often have the option of using either indexable or solid carbide thread mills to complete the job. The best choice will be determined by the unique needs of the application with respect to the flexibility of the tool and the quality of the threads it can produce.

Here’s what you need to know.

Solid…

ContinueAdded by Geoffrey Less on October 20, 2022 at 1:44am — No Comments

3 Tips For Efficient Deep Hole Drilling

When you need to drive deep holes into your piece, there are certain rules you need to follow if you want it to stay true to print. Many elements must be considered in hole-making applications: material, presetting, coolant, chip load, and tool material are among the many factors that will ultimately impact the final product.

Pay Attention To The Chip

Drill performance is often measured…

Added by Geoffrey Less on October 15, 2022 at 5:24am — No Comments

Why Use Carbide Stub Drills When Going Deep?

Increasing the performance of your machining operation not only means doing things faster, but also more accurately. The principle “measure twice, cut once” also applies to drilling through materials. More so because eros errors when cutting costly materials and parts could turn a whole piece into scrap.

When boring through materials, accuracy takes on additional dimensions. Complicated parts with holes from…

ContinueAdded by Geoffrey Less on October 14, 2022 at 6:57am — No Comments

About Common Coatings on End Mills and Drill Mills for Sale

In machining and milling operations, choosing the proper tool for the job is essential. Choosing an improperly suited tool can result in a poor-quality finished product, premature tool wear, and in extreme cases, catastrophic tool failure (shattering).

As important as it is to choose the right tool, it is also important to choose a mill or drill that has a coating that is appropriate for the machining…

ContinueAdded by Geoffrey Less on October 11, 2022 at 7:09am — No Comments

It's Important to Find the Best End Mills for Sale

End mills are important tools for machinists, but all tools have to deal with wear and tear. When it comes to replacing end mills, investing in carbide tools is the best option. Cutters made from carbide are able to outlast and outperform steel tools, even those made with high speed steel alloys. If you need new end mills for your shop, take a look at all of the high-quality carbide end mills for sale.…

Added by Geoffrey Less on October 11, 2022 at 5:53am — No Comments

Chattering: What It Is, Why It Happens, and What You Can Do About It

You may have heard it before: a distinctive, loud, almost obnoxious sound while machining: chatter. Or perhaps, if you haven’t heard it, you’ve seen the telltale sign: chatter marks, odd wave-like patterns, and other surface flaws left by vibrating tools.

Both are signs of machine…

ContinueAdded by Geoffrey Less on October 6, 2022 at 7:36am — No Comments

Machining With Quality Solid Carbide Thread Mills

One of the most common tasks we perform as machinists is adding threaded surfaces to a workpiece. Many shops are accustomed to performing this delicate process with traditional taps and dies. While the method was once thought to be efficient, new technologies have shown to produce better, more accurate, and faster results.

This is especially true for CNC machining and thread milling. Thread milling with solid…

ContinueAdded by Geoffrey Less on September 23, 2022 at 12:47am — No Comments

Trust in US Solid Carbide Carbide End Mill Manufacturers

When it comes to cutting tools like end mills, solid carbide options will always outperform other tool materials. If you're looking for the best tools for your machining shop, buying from reputable solid carbide end mills manufacturers will ensure that you're getting tools that are built to last.

End mills are incredibly useful tools. Many milling applications will necessitate the use of various specialized…

ContinueAdded by Geoffrey Less on September 14, 2022 at 8:09am — No Comments

On Choosing the Best End Mills for Aluminum

Aluminum is one of the most common metals encountered in machining operations, but choosing the best end mills for aluminum is vital to the success of the project since not all end mills will perform equally.

Take the following factors into consideration when evaluating the fitness of an end mill for a project concerning aluminum.

Why Aluminum?

Aluminum…

Added by Geoffrey Less on September 14, 2022 at 7:00am — No Comments

What Are the Practical Applications of a Chamfer End Mill?

Chamfer end mills, also known as chamfer mills or chamfer cutters, are among the cutting tools most commonly used in everyday applications by machinists. Chamfer end mills, also known as chamfer mills or chamfer cutters, are among the cutting tools most commonly used in everyday applications by machinists. …

ContinueAdded by Geoffrey Less on September 3, 2022 at 4:54am — No Comments

Why Choose Carbide End Mills Over Steel Tools

When most people think of machining tools, they naturally think of steel. High-speed steel is one of the most commonly used machining materials for a number of reasons. It is highly resistant and extremely sharp. The best part is that steel is a low-cost solution for the vast majority of your drilling and milling requirements. That is one of the reasons why many machine operators choose steel over carbide end mills for sale.…

ContinueAdded by Geoffrey Less on August 25, 2022 at 5:50am — No Comments

Why You Should Buy Carbide End Mill Sets

Several industries have experienced the benefits of improved manufacturing processes, especially those that depend on CNC milling machines. However, CNC cutters still have to deal with problems related to material fatigue, especially when it comes to cutting tools. One of the best workarounds machinists have found is to adopt the use of carbide end mill sets. They not only…

ContinueAdded by Geoffrey Less on April 25, 2022 at 6:01am — No Comments

Common Uses for Solid Carbide Drill Mills

Among the most common tools used by machinists today, we have drill mills. They come in many shapes and sizes, making them the most versatile tools in your workshop.

What makes them special is their particular ability to cut along their angled tip, giving them an incredibly extensive range of operations.

There are, of course, subtle style differences between what is usually known as an end mill and a drill mill. The point…

Added by Geoffrey Less on March 10, 2022 at 2:20am — No Comments

What You Want to See From Your Drill Bit Manufacturers

Drill bits are just one of those essential tools or materials you need in order to follow through with all kinds of construction, renovation, repairs, etc. You need high-quality, solid carbide drill bit sets that match your specifications in order to do your job for various projects. Since these are such important materials for using your drill tool on different materials, you want to make sure that you purchase from a reputable company that is known for…

ContinueAdded by Geoffrey Less on March 7, 2022 at 7:44am — No Comments

Purchasing Tools From Carbide Drill Manufacturers

Milling is a fabrication technique that involves employing high-speed cutting equipment to create pieces that are faster and more precise than working by hand. Milling on all scales is now more accessible than ever thanks to the widespread usage of CNC technology and high-quality cutting equipment. As a result, solid carbide drill manufacturers are providing high-quality…

ContinueAdded by Geoffrey Less on February 16, 2022 at 1:53am — No Comments

It's Time to Upgrade to Carbide Cutting Tools

Manufacturing with computer numerical control is a great way to produce parts quickly and efficiently. While this process has helped to revolutionize modern machining, the efficiency of a milling machine depends on two things: the material being cut and the cutting tools being used. If you want to get the most out of your milling machine then you need to be using carbide cutting…

ContinueAdded by Geoffrey Less on September 30, 2021 at 8:45am — No Comments

Do Variable Flute End Mills Make a Difference?

While milling machines are amazing tools, having to deal with tool chatter can be a not so amazing side effect of operating one. Tool chatter is a loud sound caused by tool vibrations. If you are sick of dealing with tool chatter then you have probably heard about variable flute end mills. These tools are specially designed to operate at high speeds while minimizing the effects…

ContinueAdded by Geoffrey Less on September 28, 2021 at 6:09am — No Comments

How to Choose the Right End Mill Set?

If you are running a machining operation, whether it is a small CNC in the back of your garage, or an important manufacturing business, you have probably acquired a few end mill sets to cover your needs.

As you probably know, drill bits can only cut in the axial direction, while end mills give you broader capabilities by allowing you to profile, trace and face. It means you have to…

ContinueAdded by Geoffrey Less on September 27, 2021 at 7:54am — No Comments

Latest Blog Posts

- Carbide Thread Mill NPT in Industrial Manufacturing: Strengthening Connections

- Thread Milling with Solid Carbide Mills: Tips for Success

- Why the Need for Single Pitch Thread Mills in Manufacturing?

- Why Carbide is the Chosen Material for Machining Tools

- Factors to Keep in Mind When Selecting Chamfer End Mills

- Special Qualities of Carbide as a Material for Manufacturing and Fabricating Tools

- Drill Bit Manufacturing and the Aerospace Industry

Most Popular Blog Posts

© 2025 Created by PH the vintage.

Powered by

![]()